GFRP REBAR

〰️

GFRP REBAR 〰️

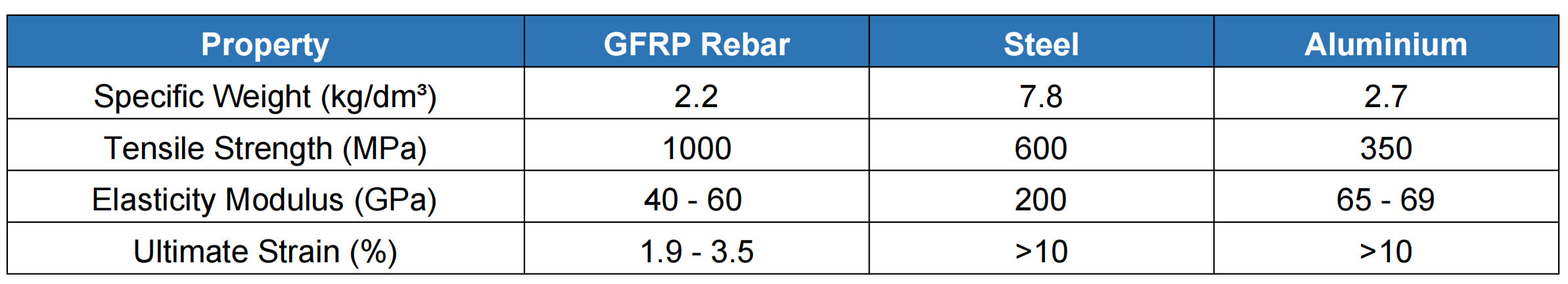

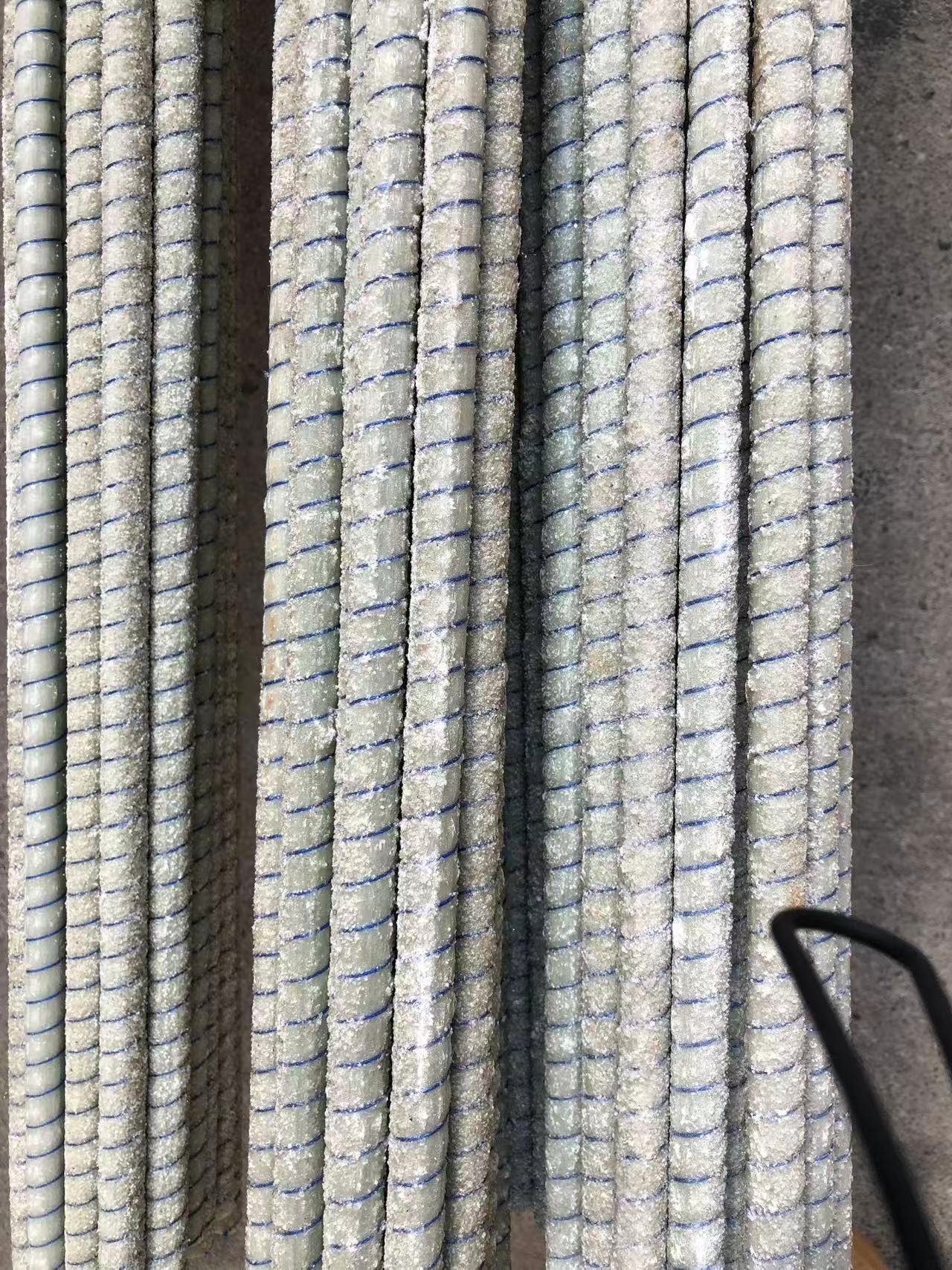

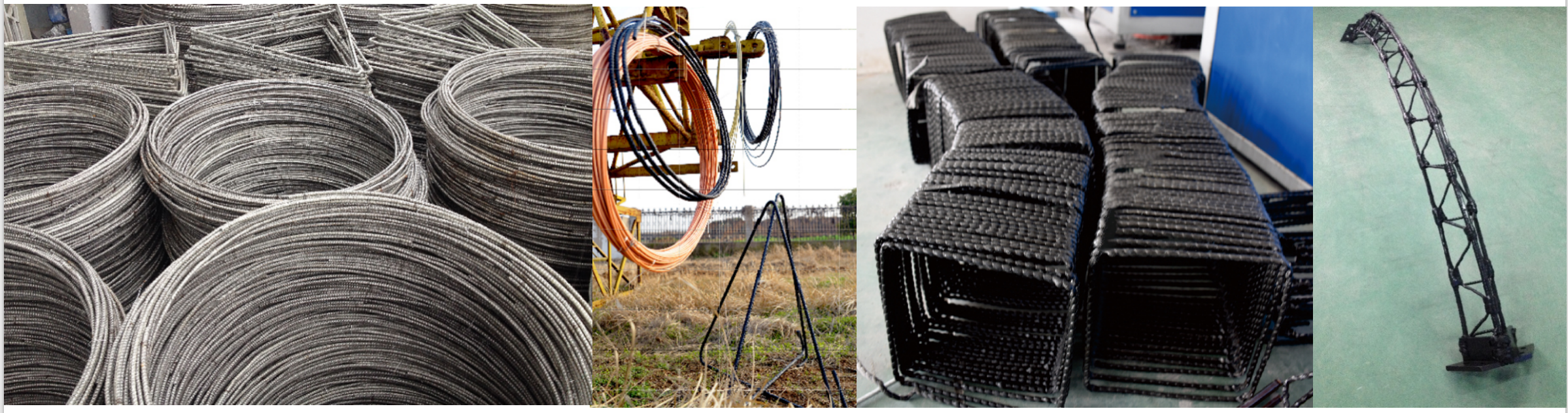

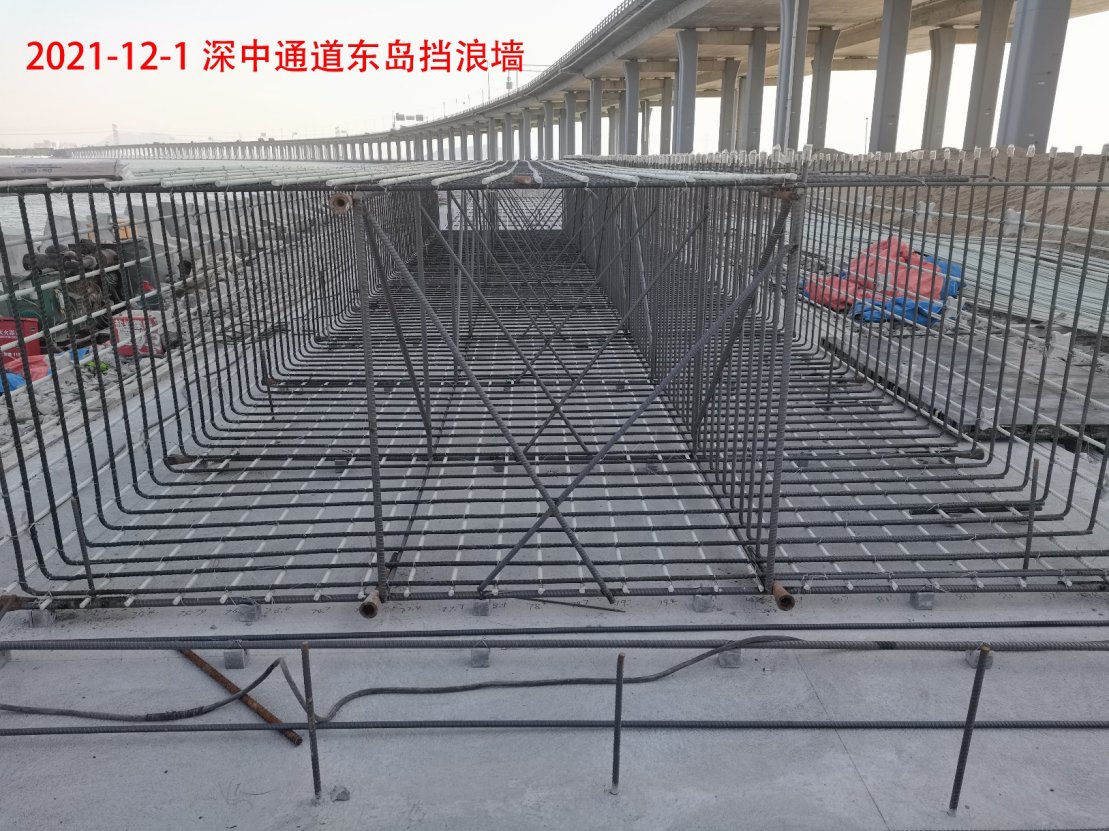

Glass Fiber Reinforced Polymer - GFRP rebar is the most widely used composite reinforcement, offering a proven and cost-effective alternative to steel in both permanent and temporary applications. Manufactured through the pultrusion process, GFRP combines high tensile strength (typically 700–1200 MPa depending on diameter) with low weight and excellent corrosion resistance, making it especially suitable for structures exposed to aggressive environments such as marine, chemical, and underground works. Unlike steel, GFRP does not rust, ensuring long-term durability and reduced maintenance costs.

A key advantage of GFRP is its versatility. Bars can be produced in a wide range of diameters and shapes, replicating nearly all conventional steel rebar profiles. This allows it to be used across applications including bridges, tunnels, retaining walls, foundations, and metro systems. This enables faster and more economical tunneling without compromising structural stability during excavation.

Field Evidence & Long-Term Studies

Extensive research and field monitoring have confirmed the durability and reliability of GFRP reinforcement:

Canada (ISIS Canada Study) — Cores taken from five in-service structures after 5–8 years of exposure to high alkalinity, freeze–thaw cycles, tidal salt water, and wet–dry cycling showed no chemical degradation or bond deterioration. Microscopic inspections (SEM, FTIR) confirmed intact fibers and matrix with strong concrete–GFRP bonding. (ISIS Canada Report, 2016)

Missouri (Walker & Southview Bridges) — Bridges reinforced with GFRP concrete for more than a decade retained stable mechanical properties, with no detectable chemical attack or fiber degradation. (Missouri Bridge Report, 2019)

Marine Durability Studies — GFRP rebars exposed to alkaline and saline conditions maintained most of their tensile and bond strength even after accelerated ageing, with only modest reductions under severe conditions (Construction & Building Materials, 2022).

Flexural Behaviour Tests (2024) — Beams reinforced with GFRP bars showed reliable structural performance, comparable load–deflection curves, and acceptable crack widths under realistic loads (Asian Journal of Civil Engineering, 2024).

Advantages Highlighted by Research

Stable tensile, shear, and bond properties under long-term field exposure.

Strong resistance to cyclic stresses, freeze–thaw, deicing salts, and marine splash zones.

Reduced risk of deterioration: even when surface cracks occur, GFRP does not corrode.

Significant life-cycle cost benefits through extended service lives projected at 50–100 years for well-designed decks and foundations.

COMPOSITE BRIDGE DECK

〰️

OCTAVUS

~

COMPOSITE BRIDGE DECK 〰️ OCTAVUS ~

Material and Application Flexibility

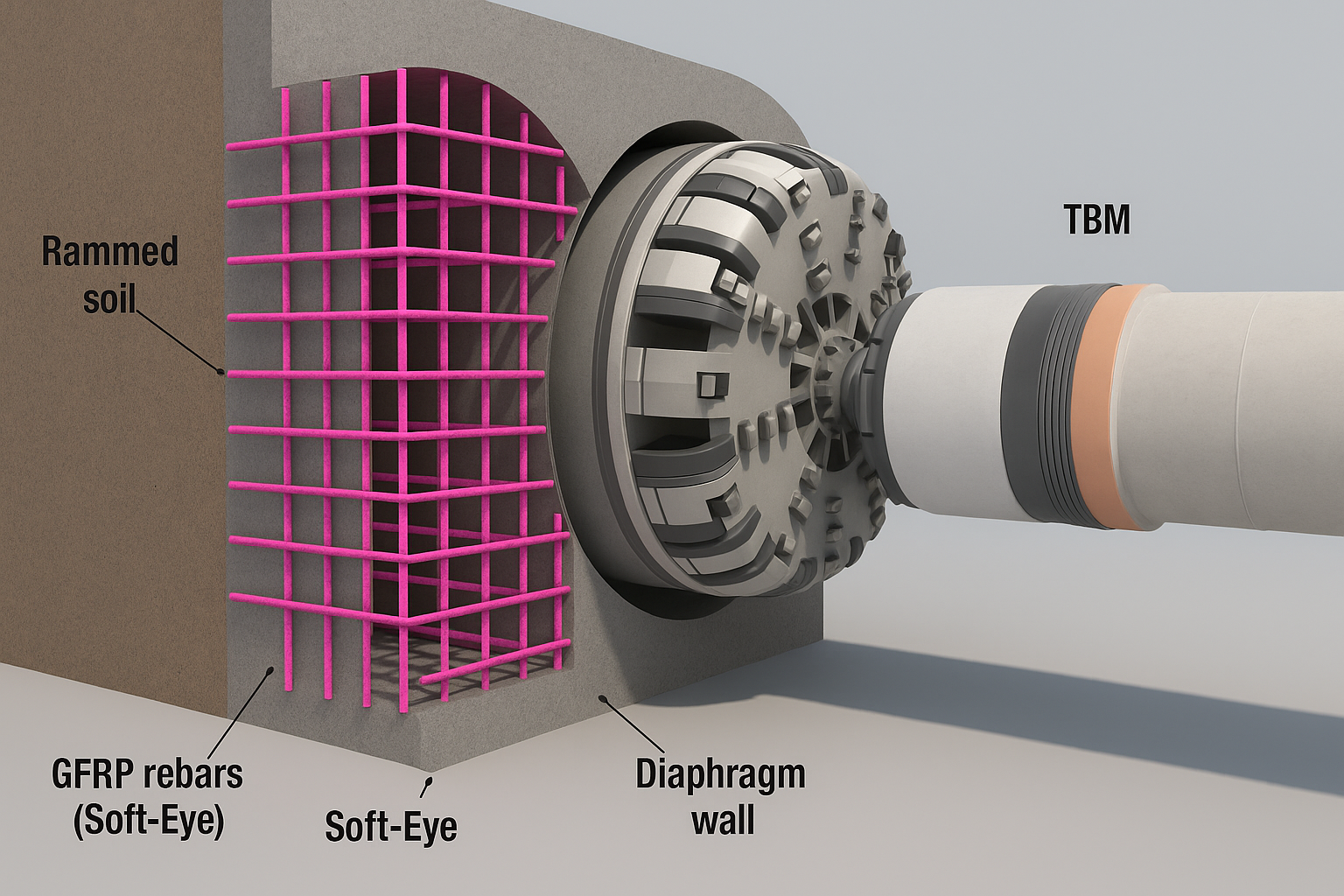

GFRP rebars can be manufactured in many diameters and shapes, replicating conventional steel rebar geometries (round, ribbed, deformed). This versatility enables use across bridges, tunnels, retaining walls, foundations, and metro systems. In diaphragm wall “soft-eye” zones, GFRP allows tunnel boring machines (TBM) to cut through reinforcement efficiently, accelerating excavation while maintaining stability.

Resin systems can also be tailored: epoxy and vinylester resins are recommended for semi-permanent and permanent structures due to their superior chemical resistance, while unsaturated polyester resins are suitable for temporary or sacrificial reinforcement applications.

With strong performance data, long-term field evidence, and adaptability in design and resin choice, GFRP rebar continues to establish itself as the smarter, more sustainable reinforcement solution for modern infrastructure worldwide.

CONTACT US

Interested or More INFO?

PLEASE FILL THE FORM.