~

CFRP REBAR

〰️

VARIANT

~

CUSTOM MADE

~

~ CFRP REBAR 〰️ VARIANT ~ CUSTOM MADE ~

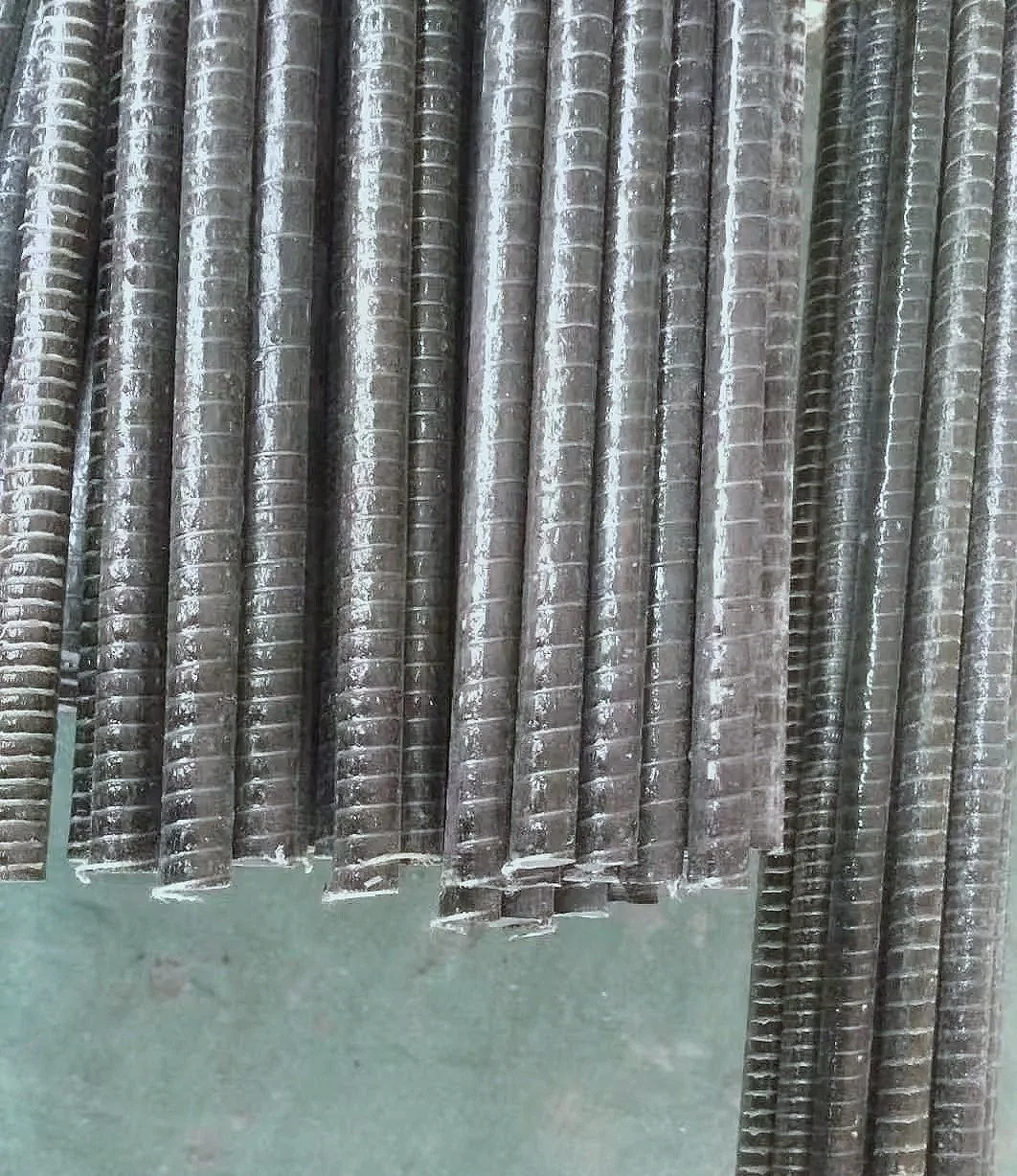

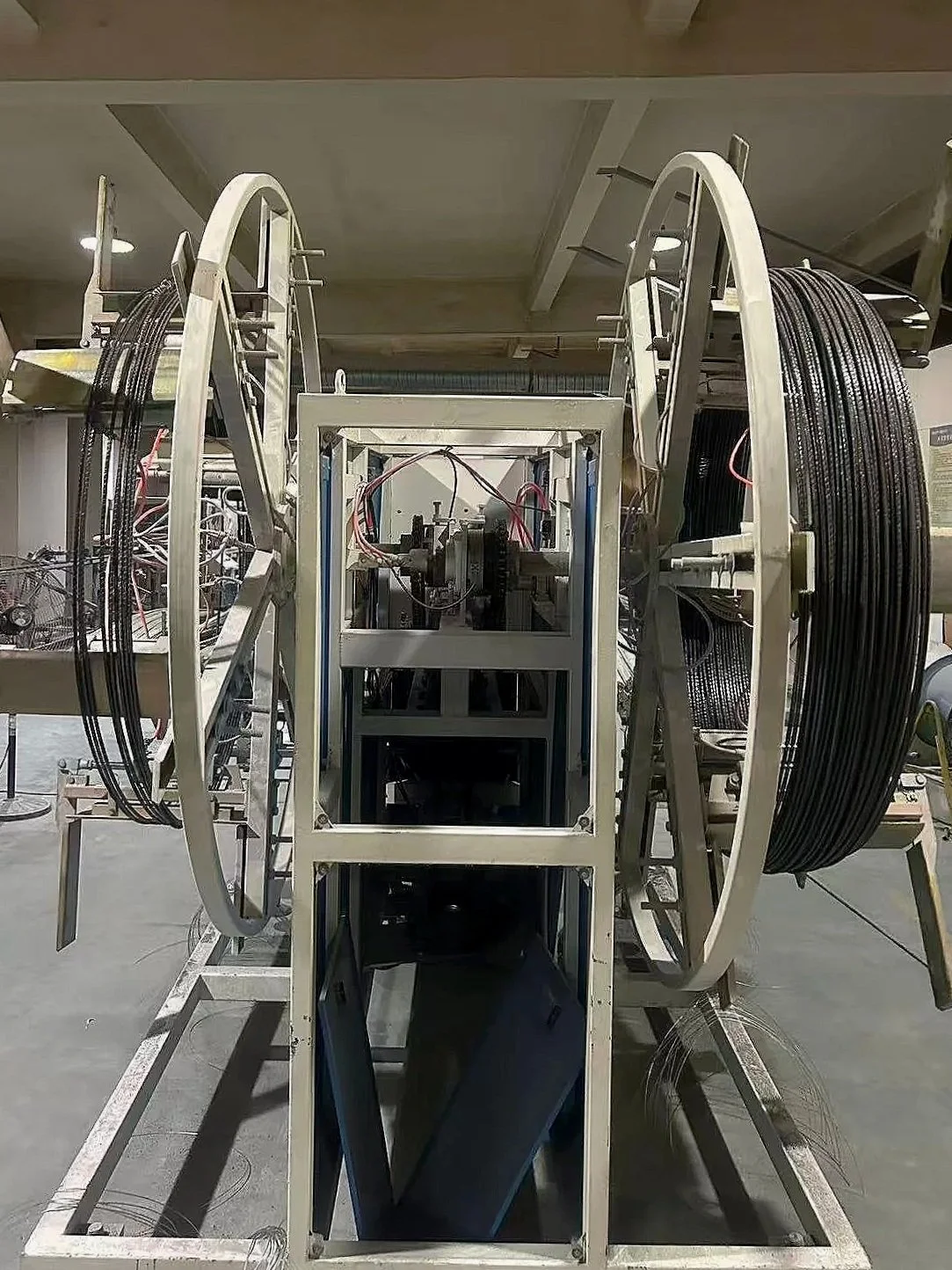

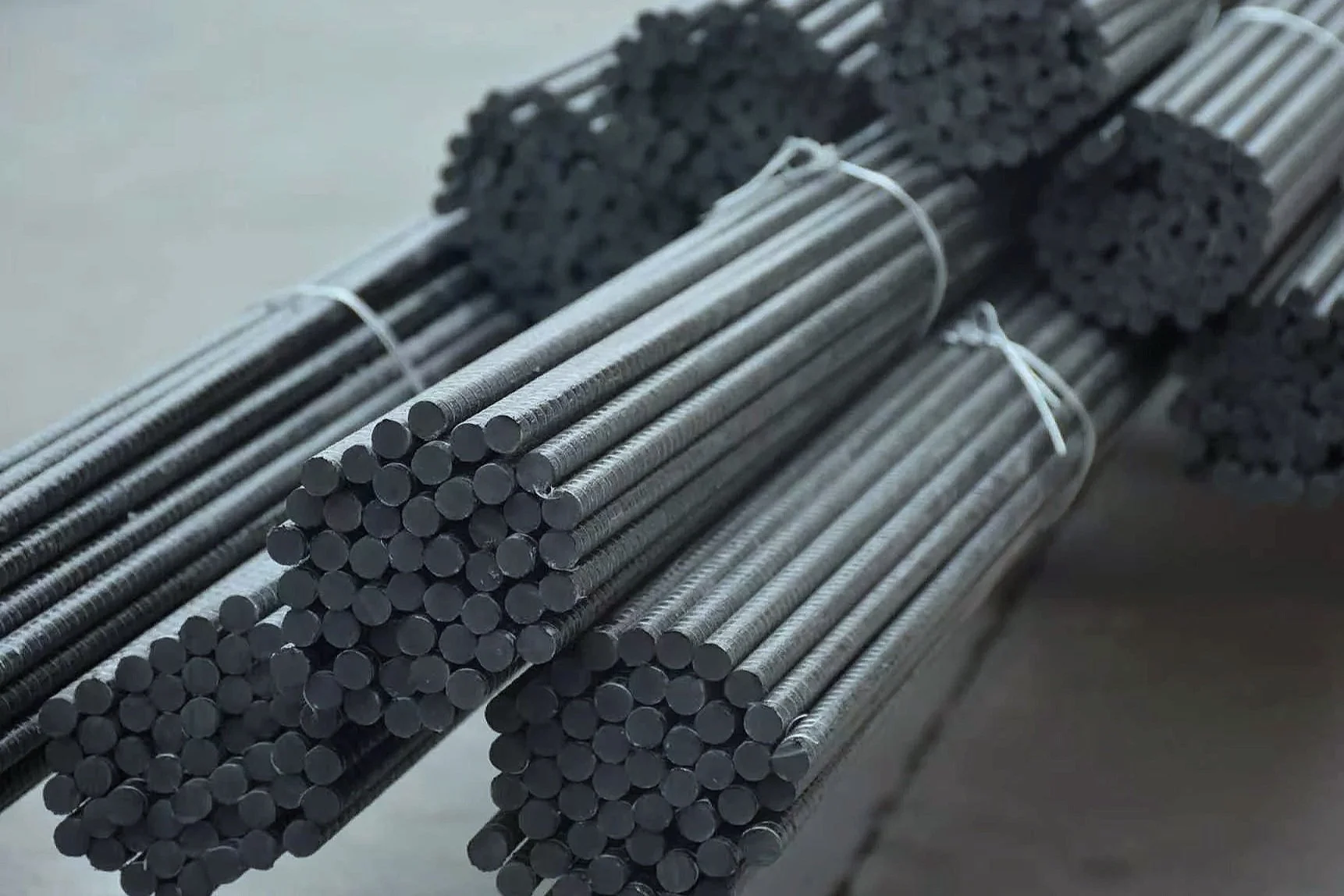

In addition to GFRP, our portfolio includes Basalt Fiber Reinforced Polymer (BFRP) and Carbon Fiber Reinforced Polymer (CFRP) rebars. Each offers distinct advantages suited to particular performance, durability, and environmental needs.

BFRP is produced from natural volcanic basalt fibers, giving it high tensile strength (typically > 1000 MPa in smaller diameters) and outstanding resistance to acids, alkalis, and harsh environments. These properties make it well suited for marine structures, docks, dams, and corrosion-prone concrete applications. Research has shown that while its stiffness is lower than steel, BFRP maintains excellent durability and long-term strength retention in aggressive conditions (MDPI, 2020; Springer, 2020).

CFRP rebar uses carbon fibers in an epoxy or vinyl matrix, delivering superior tensile strength and modulus compared to both GFRP and BFRP (~2x). It is lightweight, non-corrosive, and especially effective where maximum stiffness and reduced structural weight are critical, such as in bridges, tunnels, and high-performance retrofits. Studies confirm CFRP’s exceptional bond and tensile behavior, though its higher cost and brittle failure mode require careful design considerations (ScienceDirect, 2024).

Other emerging options, including aramid and hemp fibers, as well as hybrid rebars combining different fibers, are gaining interest for sustainable or specialized applications. Together, these FRP variants expand the possibilities of composite reinforcement, offering tailored solutions for strength, durability, weight reduction, and environmental performance.

CONTACT US

Interested or More INFO?

PLEASE FILL THE FORM.